Introduction

In the time of rapid technological change and economic globalization, the greenhouse effect has become a global issue. We live in a consumer based society, individual choices impact the environment more than ever. The public keeps concern for the state of the planet and realized the importance of reducing carbon emissions.

According to Jacobs (Facts of Car Pollution, 2017), motor vehicles produce more than 20% of carbon dioxide, 80% of reactive hydrocarbons, and 72% of nitrogen oxide emissions each year around worldwide. And most of the pollution is produced by commuters making short trips from home to work. Thus, the renewable energy and green transportation has become hot issues in the modern society, such as commuting by electric bike.

What is e-bike

Generally speaking, electric bikes are standard bicycles with a battery-powered “pedal assist.” A battery-powered motor usually mounts on the front or back wheel, depending on the type of the bike. When rider push on the pedals, a small electric motor will provide extra power and gives the rider a boost. The additional power engaged by motor complements the rider’s muscle power. It means you can get help from the motor when you are traveling long distances. Also, you can ride e-bike like a normal bike if you want. “You control your speed with your feet just like with a regular bike. You just feel really powerful and accelerate easily,” says Ed Benjamin, senior managing director at eCycleElectric.

Some electric bike comes with a handlebar-mounted throttle that engages the motor with the press of a button. Furthermore, some electric bike motors are powerful enough to carry the rider like a motorbike.

According to the New York Times, electric bikes provide same health benefits comparable to standard bike usage, the rider also can enjoy the fun of riding bike. And the electric bikes are six times more energy efficient than rail transit, and they are environmentally friendly.

The environmental effect of electric bikes

Electric bikes usually are considered as zero-emission vehicles, but the truth is that the process of manufacturing and charging them is not emission free. And the disposal of parts and batteries when they reach the end of lifecycle also should be considered an important factor.

Consumption of electricity

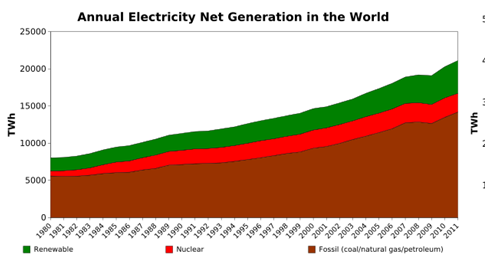

As the figure 1 shown, according to the wiki, most electricity is generated through the burning of coal or natural gas. From the figure 1 we can see the renewable energy sources are making the large contribution every year, but it still only at around 20% of total generation. So the burning of fossil fuels for electricity is a reality. However, it is hard to estimate the electric bikes emission from impacting on the electricity grid. Since the electric bike’s motor size, battery size and the user’s riding habit would all effect apart. Normally, a single electric bike has very low consumption of electricity. For example, if you were to use your electric bike for about 2000 miles each year, you could expect to use 40 to50kWh, which is the equivalent of running an air condition unit with 900Wh for about 2 days.

Environment effect of battery

Electric bike’s battery is the greatest concern when it comes to environment cost and waste. Since the batteries are not designed for long-term use right now, the life cycle of batteries usually around 1 to 3 years depending on type. However, there are many manufacturers sell battery replacements. While batteries may be recycled, but it still has some problem during the disposal process. The popular batteries of electric bikes are in several types:

- lead-acid

- nickel metal hydride (NiMH),

- lithium polymer (LiPoly),

- lithium manganese

- lithium iron phosphate (LiFePO4)

According to the wiki, lead acid is the cheapest material but most detrimental to the environment. Even with recycling, each lead-acid battery still emitted about 420 mg of lead in its life cycle, which would make the destruction of the environment. Thus, we need to avoid use lead-acid batteries. Due to the battery size limitation, the batteries of the electric bike cannot apply much impact to the environment. Also, many electric bike companies will help direct you to proper disposal locations. All in all, the environmental impact of electric bike’s battery is almost meaningless when compared to motor vehicles emission.

Electric bikes are budget friendly

The electric bike doesn’t require license and insurance, it means you can save lot money and time if you don’t have the driver license. Since you can upgrade your old bike to an electric bike by yourself. It can easily be done with an electric bike conversion kit. It can save your money, and also reduce the unnecessary waste. Also, you can buy a brand new electric bike in the bike store. Usually, 1500$ is the lowest level of the electric bikes. And for 4000$ you can get a high quality, Euro-proven, the German-engineered product with two years of comprehensive warranty support.

Also, the electric bike’s operation cost is much cheaper than cars. Based on current fuel and electricity cost, the final operation cost of e-bike could be 1/3 of the cars.

Production of electric bike

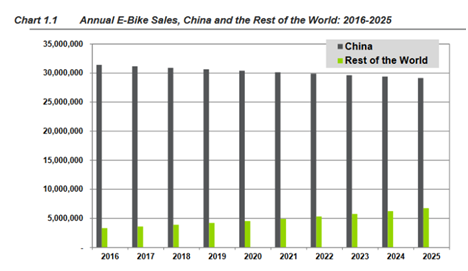

The Electric Bike Worldwide Report predicts that the electric bike industry is poised to grow to 2 billion by 2050. Eventually, 84 million e-bikes could be sold each year. China is the world’s largest manufacturer of bicycles and electric vehicles, with sales of up to 80,000,000 units, accounting for 80% of global turnover. Today around 700 Chinese companies manufacture electric bikes. According to China Bicycle Association (CBA), the top ten e-bike companies accounted for 47% of the total production in 2014. China has some 200 million e-bikes running on the road totaling CNY 100 billion in value. The value of the entire upstream and downstream industry chain has reached CNY 200 billion.

Reference list:

https://greenfuture.io/transportation/electric-moped

https://greenfuture.io/transportation/electric-bike-environment/

https://en.wikipedia.org/wiki/Electricity_generation#cite_note-9

https://en.wikipedia.org/wiki/Cost_of_electricity_by_source